Milled Ceiling with Plastic Laminate Omega 65 Profile 5 mm

Milled Ceiling with Plastic Laminate Omega 65 Profile 5 mm

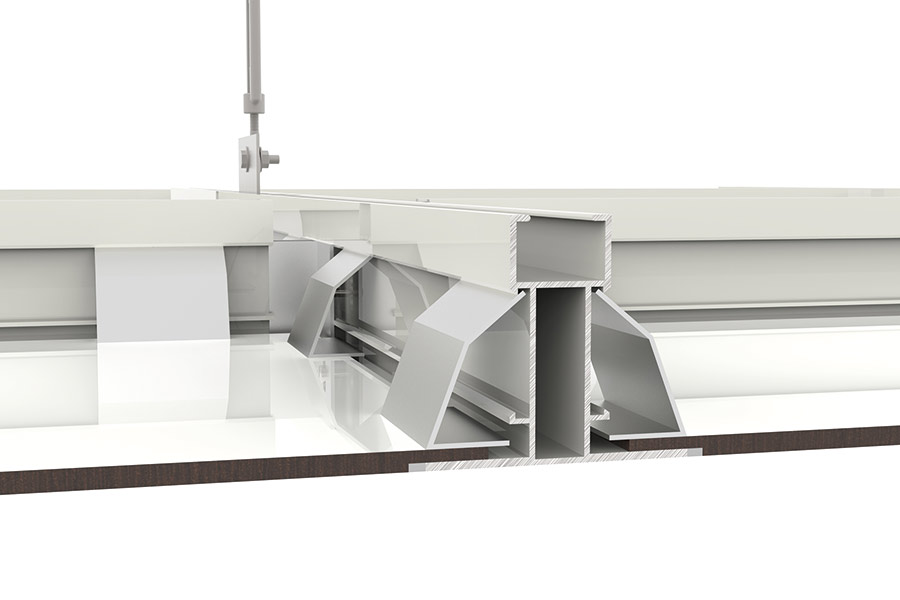

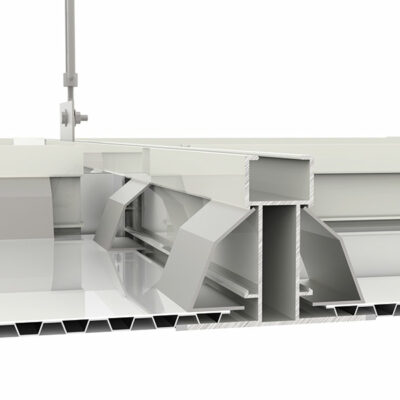

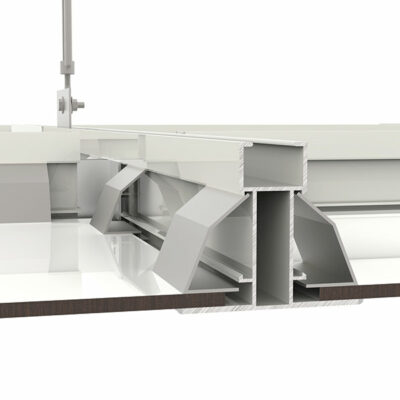

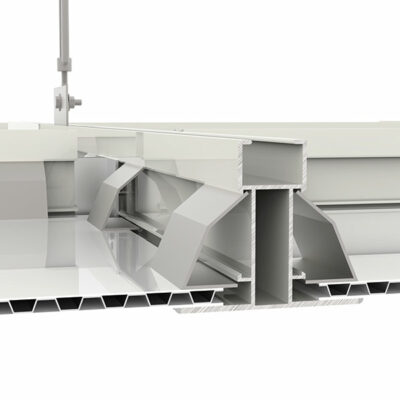

The milled Ceilings with Plastic Laminate Omega 65 Profile 5 mm (product code FC-LAM5F) for cleanrooms, produces by Delta2000, are made from an omega frame with a visible 65 mm profile in extruded anodized and/or pre-painted aluminium with infill panels for cleanrooms and they can be designed in different ways.

All the materials used are certified according to applicable laws.

Technical specifications:

Infill panelling in double-glazed plastic laminate, 5 mm thick, milled and sealed with silicone, to ensure the ceiling grid is coplanarity that guarantees it remains sealed and clean over time. Locked to the omega grid with special springs, designed by Delta 2000.

- Aluminium Omega65 Profile

- HPL infill panel (5 mm thick)

- Hanger grid with adjustable rigid threaded rods

- Silicone joint sealant

- Aluminium locks

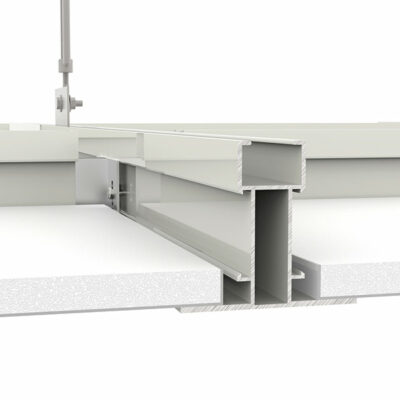

The milled ceiling with plastic laminated Omega 65 Profile 5 mm (product code FC-LAM5F) is a light-weight structure made of a flat surface placed below the actual ceiling, and it decreases the usable height of the room in question.

The cleanroom ceiling can be installed for aesthetic purposes, or as a coating with insulating, soundproofing or fire-resistant material, and it can also be used to store one or more units in the space between the ceilings.

Technical information

| CONTROSOFFITTO MODULARE FLESSIBILE | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

|---|---|

| Reaction to fire | B-s1,d0 |

| Release of formaldehyde | Class E1 |

| NORMATIVA DI RIFERIMENTO | EN 438-7 |

| MODULO | 610X610 – 1221X610 |

| TENUTA SISTEMA CONTROSOFFITTO | Load Bearing Capacity CLASS A/ 1254 N/m2 EN 13964:2014 |

Milled Ceiling with Plastic Laminate Omega 65 Profile 5 mm

The milled Ceilings with Plastic Laminate Omega 65 Profile 5 mm (product code FC-LAM5F) for cleanrooms, produces by Delta2000, are made from an omega frame with a visible 65 mm profile in extruded anodized and/or pre-painted aluminium with infill panels for cleanrooms and they can be designed in different ways.

All the materials used are certified according to applicable laws.

Technical specifications:

Infill panelling in double-glazed plastic laminate, 5 mm thick, milled and sealed with silicone, to ensure the ceiling grid is coplanarity that guarantees it remains sealed and clean over time. Locked to the omega grid with special springs, designed by Delta 2000.

- Aluminium Omega65 Profile

- HPL infill panel (5 mm thick)

- Hanger grid with adjustable rigid threaded rods

- Silicone joint sealant

- Aluminium locks

Technical information

| CONTROSOFFITTO MODULARE FLESSIBILE | TECHNICAL DESCRIPTION AND SPECIFICATIONS |

|---|---|

| Reaction to fire | B-s1,d0 |

| Release of formaldehyde | Class E1 |

| NORMATIVA DI RIFERIMENTO | EN 438-7 |

| MODULO | 610X610 – 1221X610 |

| TENUTA SISTEMA CONTROSOFFITTO | Load Bearing Capacity CLASS A/ 1254 N/m2 EN 13964:2014 |

Related products

Related products

-

OMEGA DeltaCEILING

Milled Ceiling with Honeycomb Omega 65 Profile 6 mm

-

OMEGA DeltaCEILING

Ceiling with Plastic Laminate Omega 65 Profile 5 mm

-

OMEGA DeltaCEILING

Ceiling with Omega 65 Profile aluminium plasterboard panel

-

OMEGA DeltaCEILING

Ceiling with Honeycomb Omega 65 Profile 6 mm